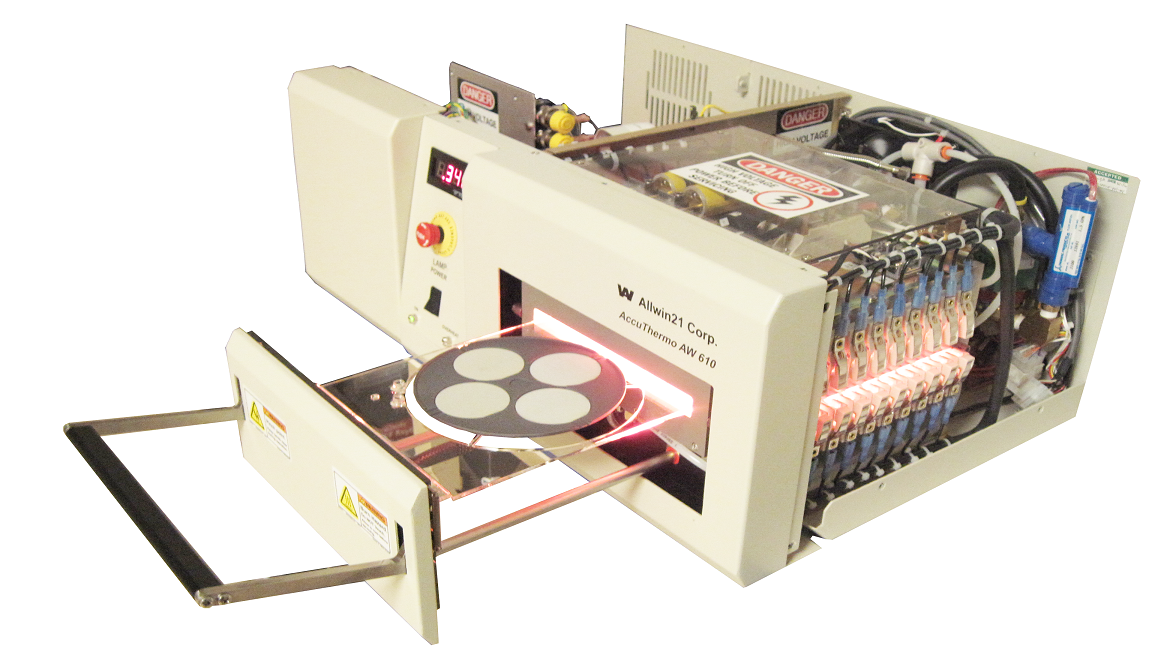

Rapid thermal processing is used repeatedly during semiconductor device manufacturing for such purposes as activating implanted dopants or changing the state or phase of materials to enhance desired attributes e g conductivity.

Semiconductor thermal processing equipment.

During cooling however wafer temperatures must be brought down slowly to prevent dislocations and wafer breakage due to thermal shock.

Semiconductor manufacturing purchasing influence advanced packaging purchasing influence 3d integration process equipment bonding wire die tab dicing scribing and die separation flipchip bga process equipment materials packaging encapsulating sealing test equipment tsv process equipment.

Browse our inventory of electronic equipment.

Temperature measurement is critical to the efficacy of semiconductor equipment.

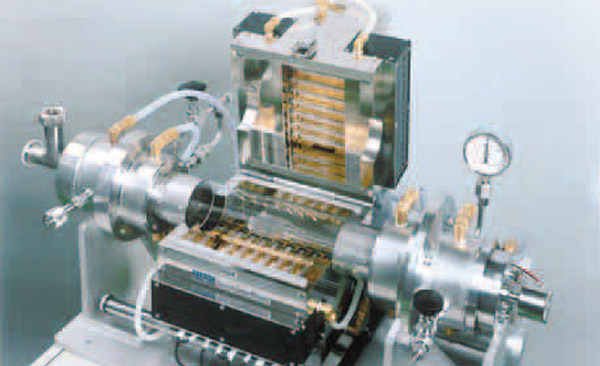

Telindy plus irad plasma enhanced batch thermal ald system telindy thermal processing system alpha α 303i thermal processing system.

Rapid thermal processing rtp is a semiconductor manufacturing process which heats silicon wafers to high temperatures over 1 000 c on a timescale of several seconds or less.

And add the specific equipment to my equipment list and hit the request info button.

Higher sample rates are needed to monitor fast ramp conditions and reliability is key to decrease failure rates.

After breaking into the semiconductor equipment industry as a leading supplier of dry strip equipment we expanded our portfolio of processing equipment to also include plasma etch rapid thermal anneal and millisecond anneal.

You can search using our search tool to the right.

We will then reach out to you to you as soon as possible.

Equipment used in manufacturing processes for transistors memory devices microprocessors crystal silicon photovoltaic pv cells and thin film pv cells all require thermal solutions.

It is a multiple step sequence of photolithographic and chemical processing steps such as surface passivation thermal oxidation planar.

Mattson technology was founded in 1988 in fremont california.

You require highly accurate and low noise solutions with varying temperature ranges for etching and wafer fab processes.